Maximizing manufacturing efficiency for a circular future

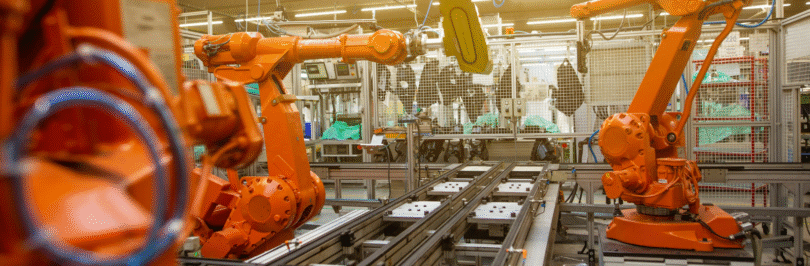

The EU aims for carbon neutrality by 2050, and manufacturers play a crucial role in achieving this through circular economy principles. A circular economy emphasizes reducing waste, reusing materials, and maximizing resource efficiency. One key metric supporting this shift is Overall Equipment Effectiveness (OEE), which measures availability, performance, and quality to reduce waste and improve operational efficiency. Poor OEE can lead to energy spikes, downtime, and material waste. Real-time monitoring through automation and IoT enables predictive maintenance and data-driven decision-making. Lean manufacturing, which aligns with circular goals, is enhanced by OEE, allowing companies to quantify both productivity and sustainability. Case studies like Handl Tyrol and White Panther show how OEE tools can cut waste, save energy, and boost performance. While OEE is just one component, it lays the foundation for a more circular and sustainable manufacturing approach—one where smarter operations today support a greener, more resilient future. Learn more about this plan.

Image source: Unsplash