New technology helps recycle dirty metal waste and significantly cut emissions

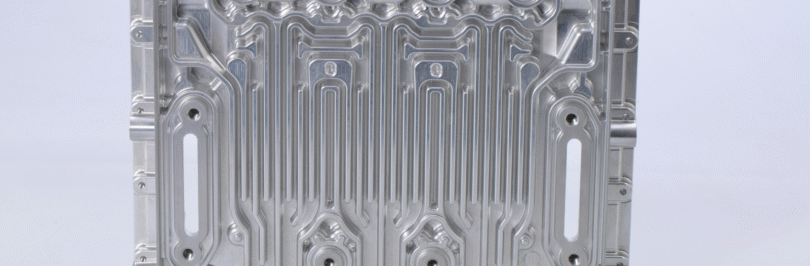

A new technology developed by a Chicago-area startup could significantly cut emissions from the global metal industry by enabling the recycling of contaminated metal waste—such as oily slivers and toxic sludge—that’s typically sent to landfills. Steel and aluminum production accounts for about 7% of global carbon emissions, and most solutions focus on overhauling traditional manufacturing. Instead, Sun Metalon offers a more immediate option: modular, oven-sized units that use intense heat to clean and recover usable metal from waste. These electric-powered units, which can operate carbon-free with renewable energy, turn waste into recyclable “pucks” or “coins.” The startup, co-founded in 2021 by former Nippon Steel engineers, recently raised $9.1 million from investors, including Nippon Steel. Their approach creates value from previously unusable scrap, helping industries lower emissions and reduce disposal costs. The recycled metal can be reused in steel mills or even repurposed onsite, closing the loop in metal production processes. Learn more about this innovation.

Image source: Unsplash